Here are a few images of the process of turning a new balance staff for a platform, the platform in question only has a couple of jewels, (7 to be precise) I thought this would mean that the pivots would be reasonably industrial, wrong. They are quite fine, (0.12 mm)

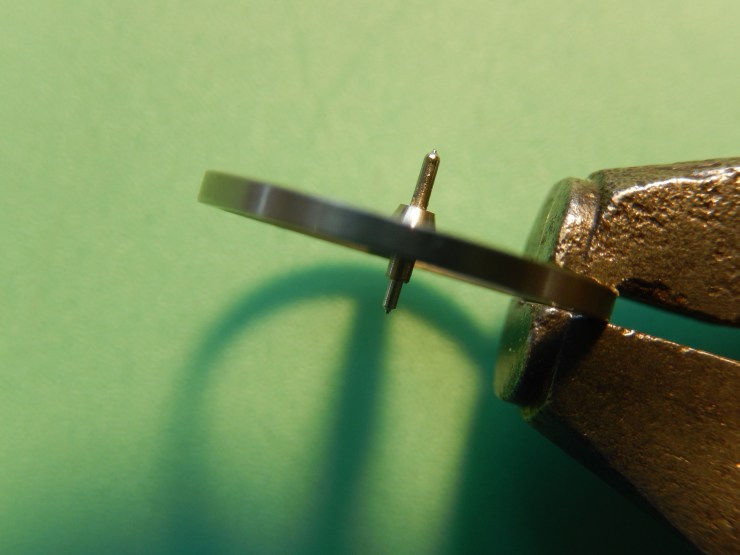

I found both pivots, one in the bottom jewel hole the other oiled to the balance spring. This makes turning the new staff easier because I can see what size they used to be, if you don’t have the bits it makes life harder as you have to guess at the length when you are turning the pivots. The image above shows the top of the balance with one broken pivot.

The image above shows the top of the balance with one broken pivot. This one shows two broken pivots, this is a fairly simple staff shape, no recess at the base of the pivots to stop oil

This one shows two broken pivots, this is a fairly simple staff shape, no recess at the base of the pivots to stop oil

Using the staking tool to knock out the old staff.

For an idea of size the image above is 6 mm long. I have chosen to turn this in the lathe in collet’s rather than between centres. The collet method isn’t quite as accurate but for this job it will be fine.

For an idea of size the image above is 6 mm long. I have chosen to turn this in the lathe in collet’s rather than between centres. The collet method isn’t quite as accurate but for this job it will be fine.

I started with the end that takes the Balance wheel.

I have turned the start of the tapered section of the staff, then the shoulder that will take the Balance, this has an undercut to help rivet the wheel onto the staff. Next is the shoulder for the Balance Spring, followed by the shoulder that gives clearance between the spring and the Balance Cock and finally the pivot. The finish that you can see above is straight from the graver so not much work needed to finish.

The other end of the staff with the pivot finished, but not taken to length.

The new versus the old, the lengths were all taken from the old by holding it up next to the staff as I turned it I did do an accurate measurement using the optical comparator once I had finished, the new part was within 0.01 mm of the original on the length of the shoulders.

Centring the staking tool over the required hole before riveting the Balance onto the staff.

Riveting the Balance onto the staff.

I like to turn the Balance and punch so that the riveting is done as evenly as possible and hopefully the Balance will run true once I have finished

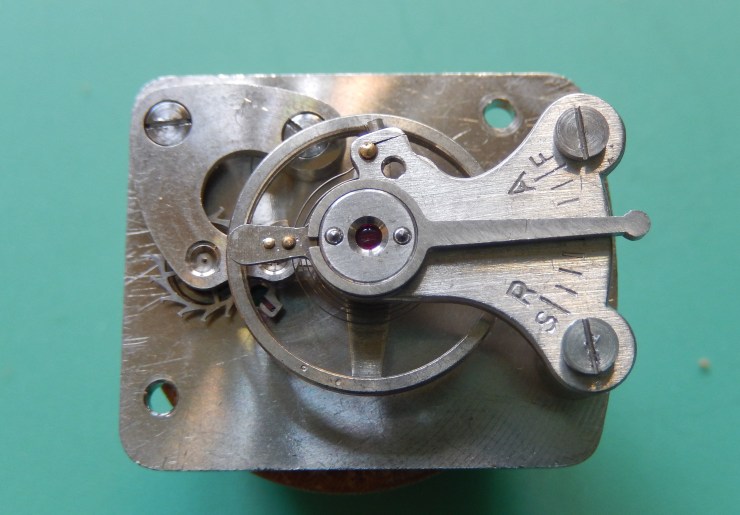

Testing the Balance staff to see how free it runs, checking for any tight spots….. should be just fine.

One platform, all cleaned and back together.