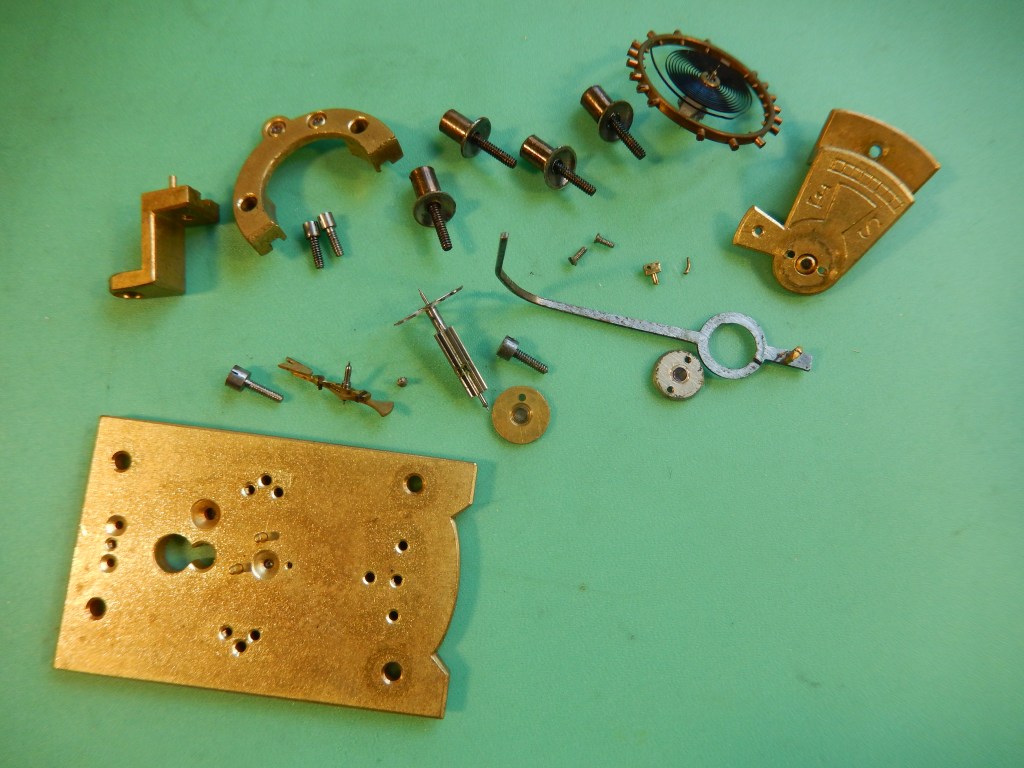

I have been working on a carriage clock which was a fairly straight forward job as far as the main clock went, the usual re-polishing and bushing a couple of old bushes which were poorly done.

A new Maltese cross for the stop work on the going side barrel the old one was missing.

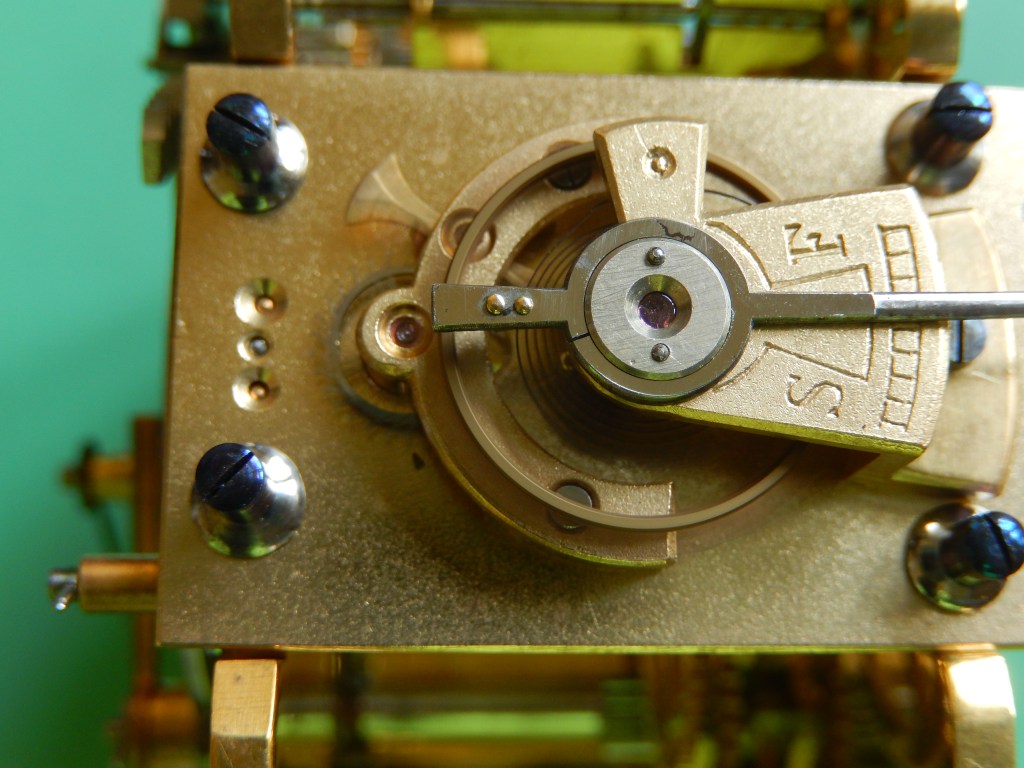

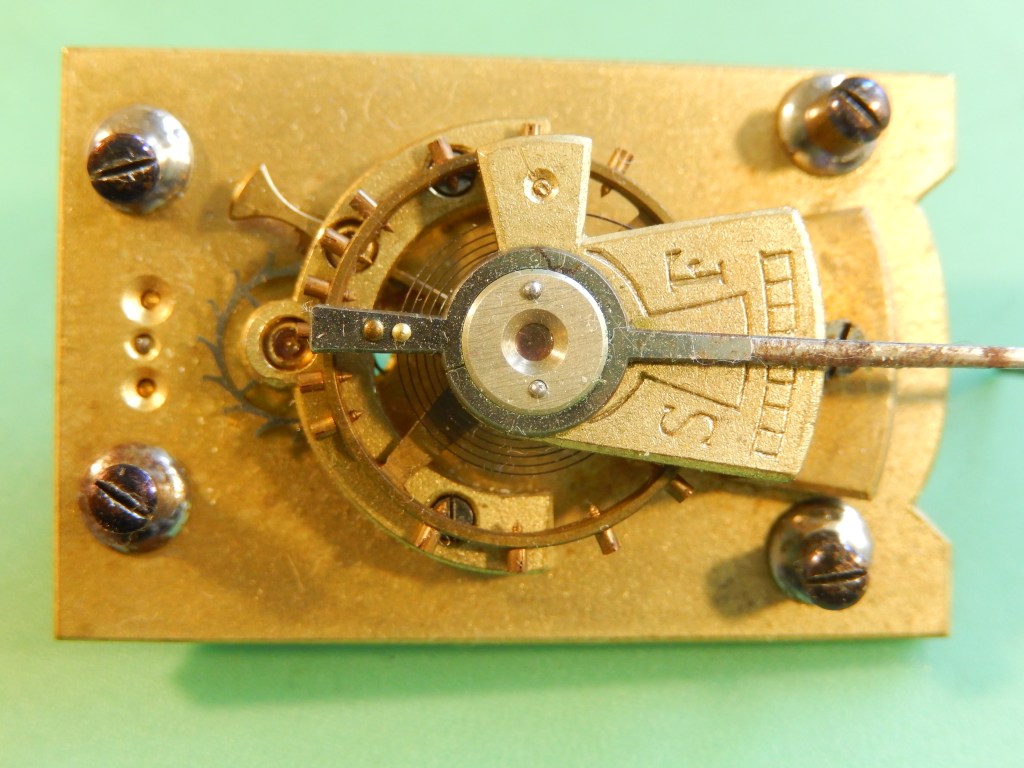

The part that required more expertise to fix was the platform, as you can see there is some rust working along the rate adjuster, there was also rust on the screws and washers for holding the platform onto the clock. Another problem I found on close inspection was the jewel at the top end of the escape wheel was loose, around 0.25 of a mm which was causing erratic running of the clock.

The jewels are the older style rub in jewel, the jewel was in good shape so it was a matter of resetting the old jewel

The tool tip used to rub the jewel in place, the screw on the side adjusts the size of the cup to regulate where you are applying pressure around the outside of the jewel. Hopefully not on the jewel or you would have a larger job on your hands.